Since overhead costs cannot be easily traced to individual products like direct material or labor costs, overhead rates help to allocate a fair share of these costs based on the activity of making the product. This allows businesses to capture the full cost of production in their accounting. Determine the predetermined overhead rate by dividing the total estimated overhead costs by the estimated activity level.

Introduction to Overhead Rate Calculation in Accounting

For example, the costs of heating and cooling a factory in Illinois will be highest in the winter and summer months and lowest in the spring and fall. If the overhead rate is recomputed at the end of each month or each quarter based on actual costs and activity, the overhead rate would go up in the winter and summer and down in the spring and fall. As a result, two identical jobs, one completed in the winter and one completed in the spring, would be assigned different manufacturing overhead costs.

3 Activity-based Costing

Once costs are broken down, small businesses can assess if any categories are excessive. Renegotiating contracts with vendors may yield savings on supplies or services. If you’d like to learn more about calculating rates, double declining balance depreciation method check out our in-depth interview with Madison Boehm. B2C usually involves more picking and packing time for smaller orders, while B2B might have more equipment usage for bulk orders. Assume High Challenge Company makes two products, touring bicycles and mountain bicycles.

Breaking Down Overhead Costs: Fixed and Variable

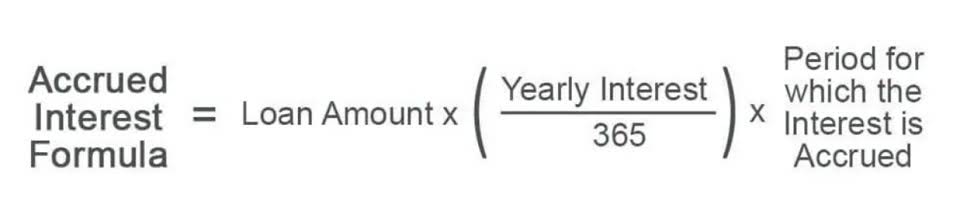

- The third step is to compute the predetermined overhead rate by dividing the estimated total manufacturing overhead costs by the estimated total amount of cost driver or activity base.

- Forecast future overhead costs based on historical data, industry trends, and expected changes in production volume.

- They enable businesses to compare actual overhead costs with the estimated rates, identify variances, and take corrective actions if necessary.

- In a standard cost system, accountants apply fixed manufacturing overhead to the goods produced using a standard overhead rate.

- If Department B has overhead costs of $30,000 but direct costs of $70,000, then its overhead rate is 43%.

- Based on the above information, we must calculate the predetermined overhead rate for both companies to determine which company has more chance of winning the auction.

- A pre-determined overhead rate is the rate used to apply manufacturing overhead to work-in-process inventory.

Once the activities have been identified, the next step is to assign costs to them. This can be done by using a variety of methods, such as direct tracing, engineering estimates, and statistical analysis. Using last year’s overhead rate without considering changes can lead to pricing mistakes. Optimize processes – Streamline workflows around everything from inventory to invoicing to save time and cut labor costs. You’ll master the key formulas, learn how to allocate costs properly across departments, see real-world examples, and discover QuickBooks best practices to control overhead expenses. These estimates were made last year and will be used during all of the current year.

Predetermined Overhead Rate (POHR): Formula and Calculation

Hence, one of the major advantages of predetermined overhead rate formula is that it is useful in price setting. Look at the overhead rates computed for the four activities in the table below. Note that the total overhead for current year is $2,000,000 using activity-based costing, just as it was using a traditional costing method. The total amount of overhead should be the what is predetermined overhead rate same whether using activity-based costing or traditional methods of cost allocation to products. The primary difference between activity-based costing and the traditional allocation methods is the amount of detail; particularly, the number of activities used to assign overhead costs to products.